CNC machining services by ChangTong,offer turning and milling capabilities using the latest manufacturing technology to guarantee great results with precision machining.

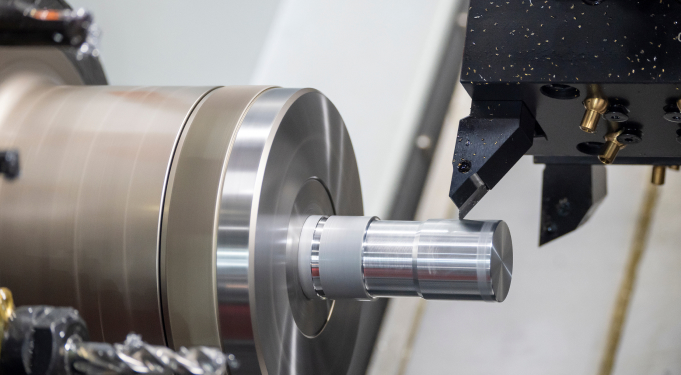

Precision CNC Turning Services

CNC turning is ideal for creating cylindrical parts. During this subtractive machining process, the software controlling the lathe ensures high accuracy and repeatability throughout the production cycle.ChangTong's CNC turning services offer state-of-the-art machinery suitable for large-scale manufacturing but we also accept one-off small jobs.

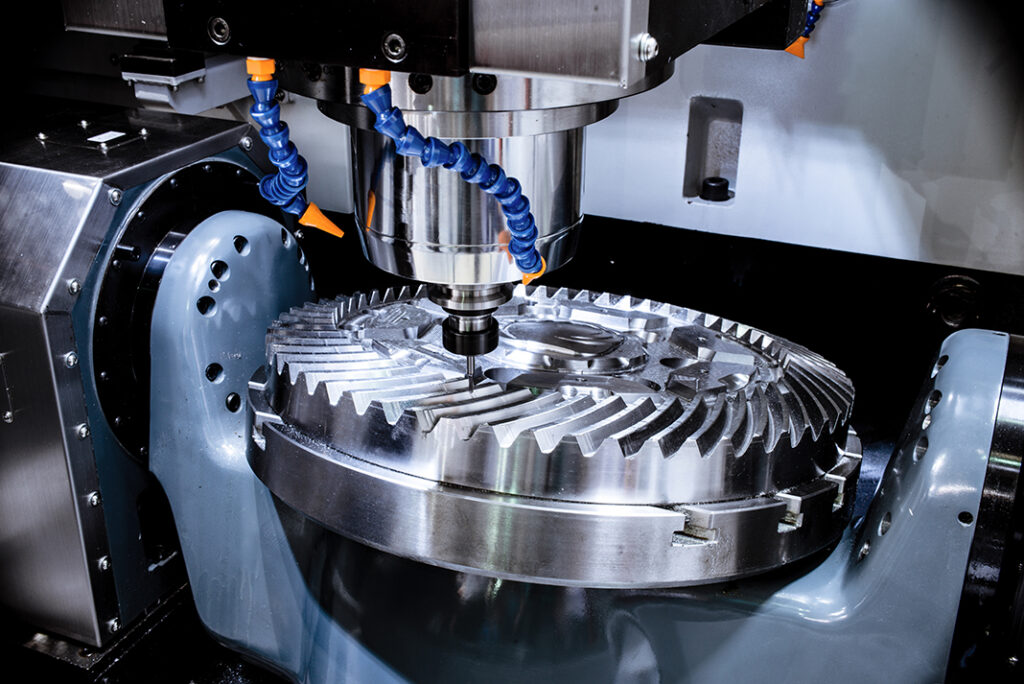

Precision Milling Services

Looking for low cost CNC milling parts with unparalleled quality? LongYan ChangTong Machinery Equipment Co.,Ltd. is a professional China CNC company provides superior precision CNC milling services with advanced machines including CMC milling center and milling machining centers from the general 3-axis to 5-axis and accomplished machinists. Our experienced operators proficient in CAD (computer-aided design) and CAM (computer-aided manufacturing) programs are always finding the best way to produce the highest quality CNC milled parts & components for clients. With strong capabilities and extensive experiences, we can provide top-grade but cost-effective custom CNC milling services from China including 3-axis CNC milling and 5-axis milling for high-speed CNC manufacturing, rapid prototyping, and precision CNC milling and turning.

CNC Drilling Service

Drilling is the cutting process in which the workpiece does not move, making the cutter move, aligning the cutter center with the hole center, and making the cutter rotate. CNC Drilling is primarily done on CNC machines including CNC milling machines and lathes. CNC drilling service produces round holes, typically for machine screws and bolts. Drilling can process CNC drilling parts with metals, hard plastics, wood and most other rigid materials. There are several types of drilling machines available for CNC, including these drill presses: Upright, Bench and Radial. When in use, the step-by-step process for CNC drilling includes:

- The operator uploads and accesses the computer-aided design (CAD) or computer-aided manufacturing (CAM) file.

- The operator installs the appropriate drill bit and secures the designated material on the table.

- The operator starts the drilling process through the control panel or interface.

- The spindle lowers, drilling the appropriate hole sizes and diameters.

LONGYAN CHANGTONG MACHINERY EQUIPMENT CO., LTD

Tel:

Production base:

364000,Longyan,Fujian,China.

Page Copyright 2021 LONGYAN CHANGTONG MACHINERY EQUIPMENT CO., LTD. All rights reserved. 闽ICP备17001320号 Power by 300.cn

86 15860100246

86 15860100246

Message

Message