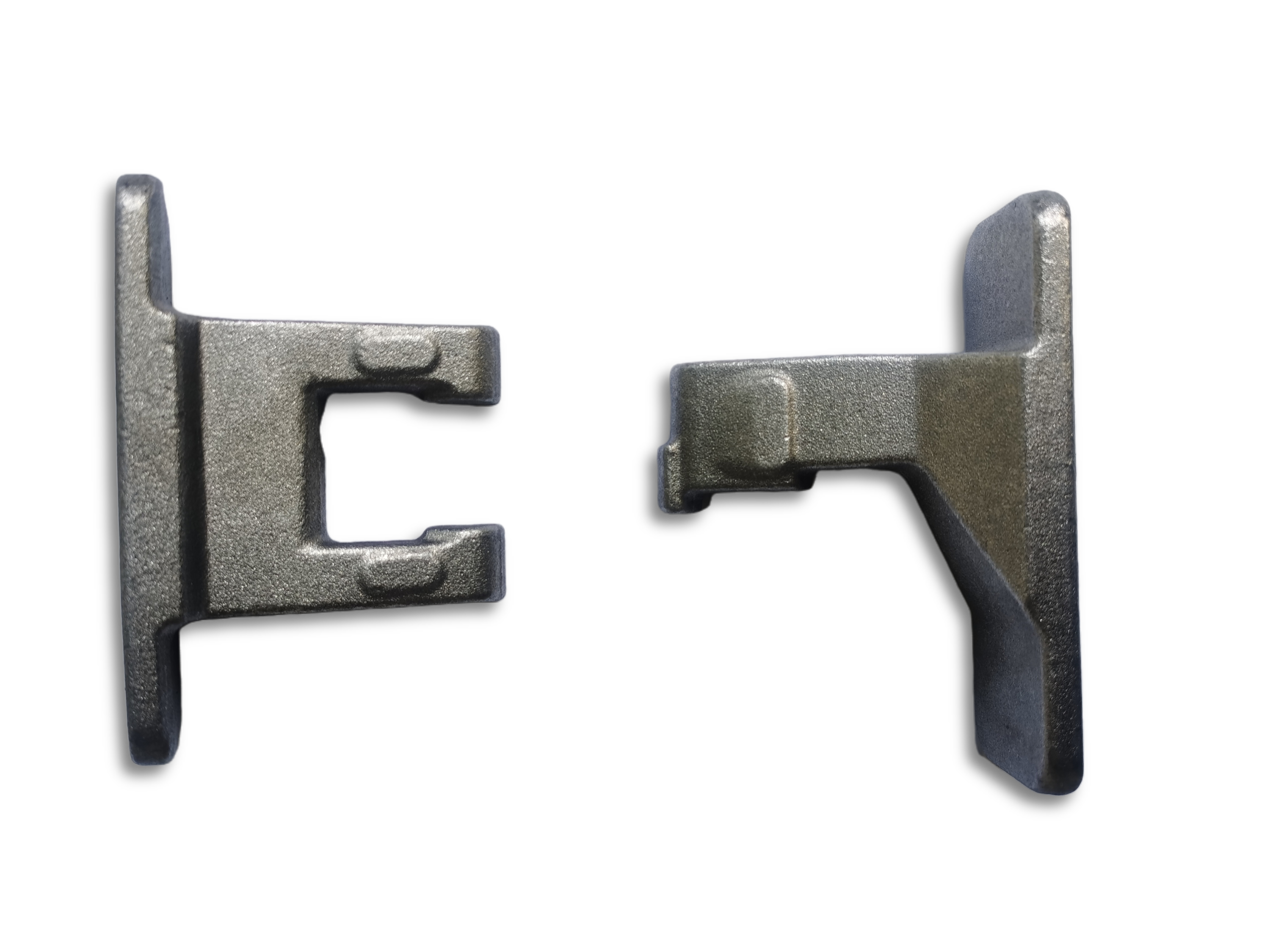

Forged auto part door hinge buckle hot forging Customized auto forging

Forged auto part door hinge buckle hot forging Customized auto forging

The forging process performed above the recrystallization temperature of the metal is called hot forging. Hot forging is also called hot die forging. During forging, the deformed metal flows violently, and the contact time between the forging and the die is long. Therefore, the mold material is required to have high thermal stability, high-temperature strength and hardness, impact toughness, thermal fatigue resistance and wear resistance, and easy processing. Light-duty hot forging dies can be made from low alloy steels.

Forging method. Except for large and medium-sized free forgings that use steel ingots as blanks during hot forging, general forgings use various metal bars as blanks. Before forging, the bar material is generally cut into pieces according to the required size on special blanking equipment. The commonly used forging methods are as follows:

Sawing hot forging. Sawing and blanking are often carried out on circular saws, hack saws, and high-speed band saws. The characteristics of sawing are that the cut section is flat and the size is accurate, but the productivity is low, there is a loss of the saw edge, and the loss of the saw blade and saw disk is also relatively large. The high-speed band saw is relatively advanced cutting equipment with high production efficiency and a regular blank shape.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LONGYAN CHANGTONG MACHINERY EQUIPMENT CO., LTD

Tel:

Production base:

364000,Longyan,Fujian,China.

Page Copyright 2021 LONGYAN CHANGTONG MACHINERY EQUIPMENT CO., LTD. All rights reserved. 闽ICP备17001320号 Power by 300.cn

86 15860100246

86 15860100246

Message

Message