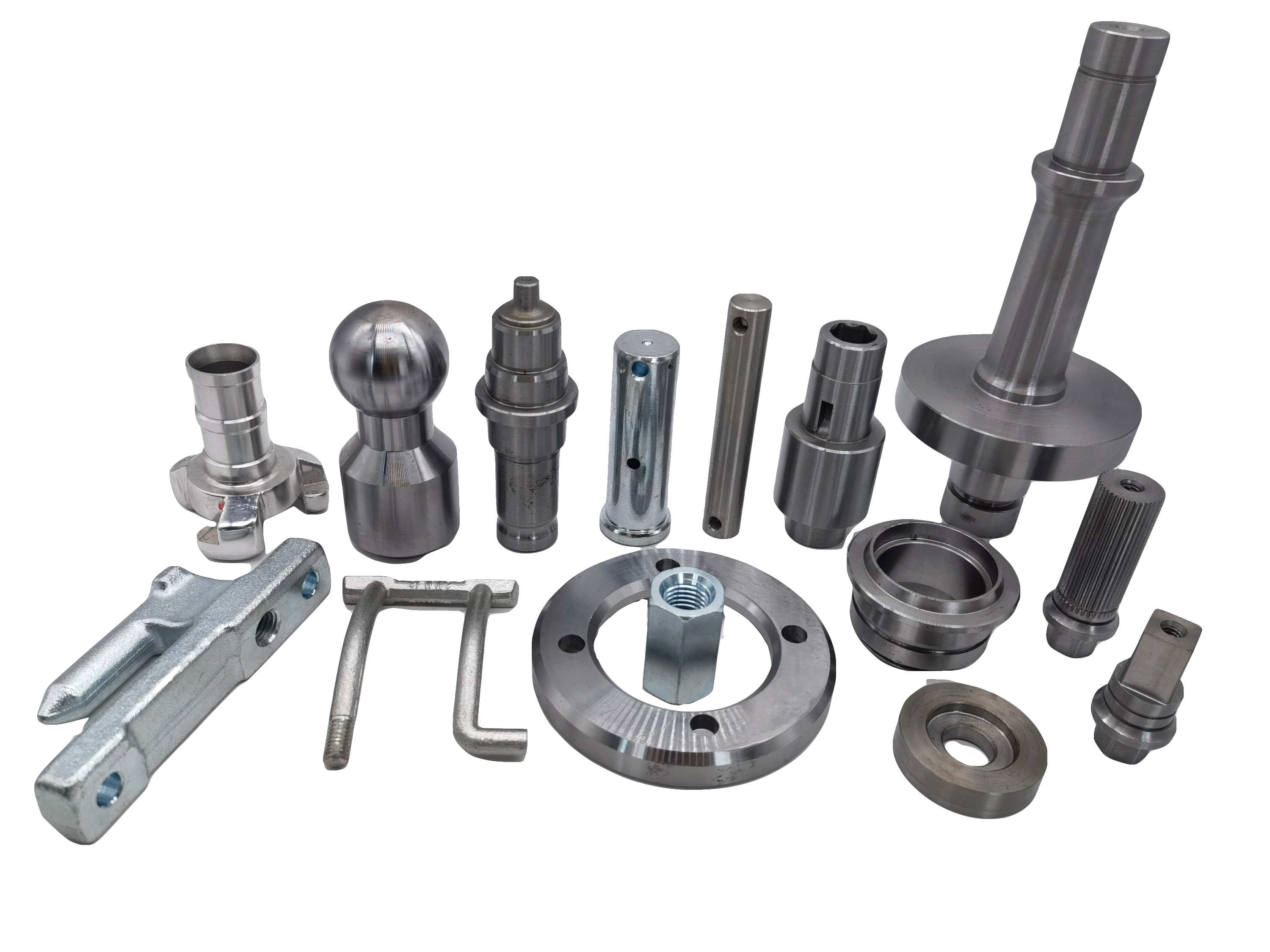

When determining the final forging temperature of Custom steel forging on sales, it is necessary to ensure that the steel has sufficient plasticity before final forging and that the forgings can obtain good microstructure and properties. Therefore, the final forging temperature of Custom steel forging on sales should be higher than the recrystallization temperature to ensure complete recrystallization after forging, so that the forgings can obtain fine grain structure.

As far as the carbon steel of Custom steel forging on sales is concerned, the final forging temperature cannot be lower than the A1 line of the iron-carbon balance diagram. Otherwise, the plasticity will be significantly reduced, the deformation resistance will increase, the work hardening phenomenon will be serious, and forging cracks will easily occur.

For the hypereutectoid steel of Custom steel forging on sales, the final forging temperature should be 15-50℃ above the A3 line, because it is located in the single-phase austenite region. Uniform organization and good plasticity. However, for low-carbon steel (with a carbon content of less than 0.3%), the final forging temperature can be reduced to below the A3 line. Although it is in the (γ+α) dual-phase region, it still has sufficient plasticity, and the deformation resistance is not too high. Expanded forging temperature range.

Through the above introduction and analysis of the Final forging temperature of Custom steel forging on sales, hope it helps you.

86 15860100246

86 15860100246

Message

Message